Uniloy Blow Molding Machine, and Reciprocating Blow Mold Machine

Velocity Equipment Solutions provides top quality blow mold machines to clients throughout the world. With four different field offices, we are proud to provide parts and used machines in the Uniloy line including the Uniloy Blow Molding Machine and the Reciprocating Blow Mold Machine. From high-output machines to large capacity bottling, Uniloy is known for quality performance with low costs. Following a modular approach, each Uniloy blow molding machine can be customized to a client’s needs.

Modular pieces can work in a number of different footprints and include:

- Extruder size

- Head capacity

- Clamp force

- Platens dimensions

- Multiple head configurations

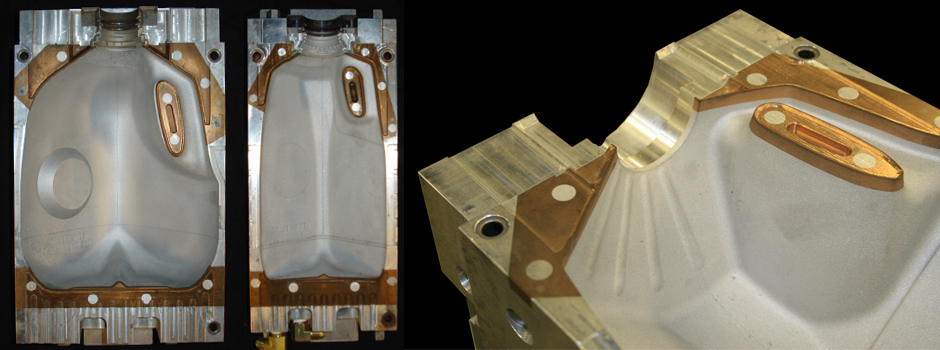

Uniloy Blow Molding Machine

Uniloy Blow Molding Machine

Uniloy’s versatile molding process offers the most flexible production capabilities. Providing molders with the most possibilities for their market, the Uniloy Accumulator Head technology is the best choice for molders to meet the demand of their clients as well as increase production. This versatile blow molding process works with many different types of resin and can produce many different sizes and types of products.

- Industrial packaging

- Fuel tanks

- Toys and sports items

- Nautical accessories

- Household and gardening items

- Automotive parts

- Flat panels

- Large and heavy parts

Continuous Extrusion blow molding provides significant energy saving with the capability of multilayer coextrusion. Cost-effective solutions can be added through configurations such as double head machines with a single clamp or single head with a double clamp. Continuous Extrusion with Parison Transfer (UMC.PT Series) provides the capability of multilayer coextrusion with significant energy savings, fast cycle times, and better parison profiling.

Uniloy Reciprocating Blow Mold Machine

The Uniloy Recip Series includes advanced molding technology for reciprocating screw intermittent-extrusion. The preferred choice of molders around the world, this series produces a high volume of lightweight monolayer and three-layer containers. The high-quality Recip Series has been engineered to also provide the high quality expected from clients with the lowest possible cost per container and excellent speed manufacturing.

Ideal for larger containers and where extended shelf life is required, the Uniloy Reciprocating Blow Mold Machine is the choice for many molders for reliable production of food and beverage containers. Edible oils, dairy, and other products with various stability thrive in bottles made from the Multi-layer and Clean-Blow™ systems. These systems also provide reliable reciprocating screw intermittent- extrusion blow molding technology for handle and non-handleware. Standard for HDPE and PP containers, the Uniloy Reciprocating Blow Mold Machine can be customized with the capability of processing other materials.

Additional services provided by Velocity Equipment Solutions for your Uniloy Blow Molding Machine include:

- Supplier of replacement parts

- Customized upgrades

- Modulization for versatility

- Technical service

- 24/7 troubleshooting

- In-stock parts

- Same-day shipping

READY TO GET STARTED?

Contact US TODAY for a Quote OR AN APPOINTMENT.

Velocity Equipment Solutions Global Headquarters

2618 West State Street

New Castle, PA 16101, USA

TOLL FREE: 800-521-1368

UK Sales Office and Distribution Center

Units 4 E+F, Manor Business Park, Grants Hill Way

Woodford Halse, Nhants, NN113UB

United Kingdom