Secondary Plastic Bottling & Water Bottling Equipment

Velocity Equipment Solutions builds the same quality into our secondary equipment, enabling you to further streamline your processes and expand the services provided by your Velocity Bulk Water Bottling System.

CONTACT US

This equipment includes:

Velocity Capper Units

- Presser-belt cap sealing

- Cap lubrication mechanism

- Processes up to 3,000 BPH

- Stainless steel componentry throughout

- Spinner bowl to orient caps into correct position

- Adjustable rod-style open cap chute for easy cleaning

- Overhead hopper with vibrator and low-level switch

- Air regulators at presser-belt and cap-chute foot

- All material is RoHS compliant

Capper Unit Options

- Multiple size bottle adjustability

- Fiber-optic sensors for cap-present sensing and no cap alarm

- Cap chute UV lamp

- Ionic cap de-dusting mechanism

- Floor-level hopper with elevator (various tub sizes available)

Velocity Fillers

- In-Line Models (3-head to 6-head)

- Side-Shift Models (6-head to 14-head)

- Standard pressure filling, timer-based pump with VFD speed controls

- All componentry in the food zone is NSF component certified

- All material is RoHS compliant

- Overflow recovery system to minimize water loss

Filling System Options

- CIP (clean in place) ready

- Flow-metering with monitoring process for bottle filling accuracy

- Non-contact filling

- Multiple size bottle adjustability

- HEPA filtration

- Chamber lighting

- SS braided fill hoses

Inspection

A variety of inspection equipment is available to complete your Velocity Bottling Systems line. These include the following optional devices ready to automate your process further. Contact us for more information.

- Visual light inspection tables

- Leak detectors

- Containment detectors

- Vision/Camera-based inspection

Contact Tank

Contact Tank Features

- 125 to 1,500-gallon models

- Manhole access with window

- Flanged water feed inlet with SS float valve

- SS construction

- Cone bottom and domed top

- Lift-lugs

- Sampling drain and ozone diffuser system

- 3″ or 4″ tri-clamp outlet with ball valve

- All material is RoHS compliant

Contact Tank Options

- Side-sight level tube

- CIP ready with spray-ball

- Additional couplings

- Ozone destruct unit

- HEPA breather

Decapper Units

Velocity 600 Semi-Automatic Decapper Unit

The Velocity 600 Semi-Automatic Decapper is a semi-automatic designed for manual operation.

Features

- Removes and discards Non-Spill caps from empty 3, 5, & 6-gallon returnable type bottles with 55mm neck finish

- Stainless steel construction with clear Lexan coverings

- 49-1/2″ overall height

- System requires clean, dry compressed air supply for operation; 3 CFM @ 90 PSI

- Electricity not required

- All material is RoHS compliant

Velocity 1800 Automatic Inline Decapper Unit

The Velocity 1800 Automatic Inline Decapper is the fully automatic, top quality solution for large water bottling operations.

Features

- Automatically removes and discards caps from empty 5-gallon bottles at speeds up to 1,800 BPH

- Designed for over conveyor mounting

- Stainless steel construction

- Customized to fit top-of track height requirements

- Right or left-hand cap discharge models available

- Bottle-backup sensor prevents back-up of bottles into the decapper

- Built-in sensor allows bottles without caps to pass through

- Audible alarm sounds if cap is not removed completely

- Compressed air required: 15 CFM @ 90 PSI

- 120VAC/1ph/60 Hz standard

- Control panel with touch-screen

- Requires minimum accumulation of 10’ power conveyor for proper operation

- All material is RoHS compliant

Automatic Options

- Multiple bottles size capable

- Crate capable

- Bottle rejection station

- Power conversion package

- Control panel upgrade

- Conveyor sections

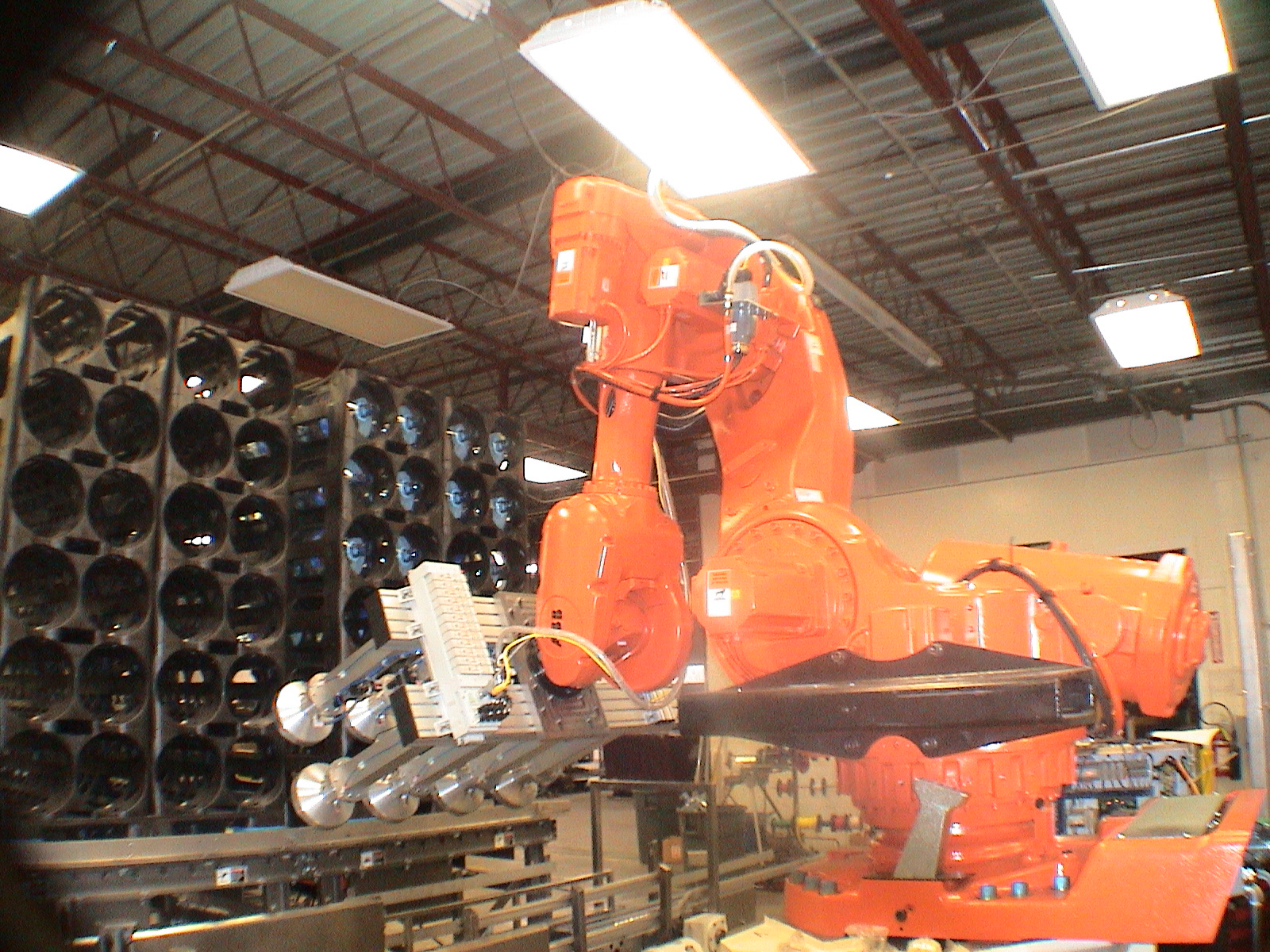

ROBOTICS

Velocity can completely design a robotic solution to fit your needs.

Features

- Full bottle load only scenarios

- Full bottle load and empty bottle unload scenarios

- Rack conveyor-gravity, powered, turntables, scissor-lift tables

- Wide range of tooling options

- Twin robot solutions for high-speed efficiency

- Multiple rack style/size sensing devices

- Photo/vision systems

- Steel and/or plastic racks solutions

- All material is RoHS compliant

PROCESS OPTIONS

System Options

- System power supply conversion to local electrical specifications

- Other controls packages – Omron, Allen Bradley

- Multiple size bottle adjustability

- Control cabinet air-conditioning

- Stainless steel control panel upgrade

- Additional power bottle conveyor

- Additional gravity bottle conveyor

- Enclosure for power conveyor

- Conveyor drip pans and water drainage system

- Electrical cable containment system upgrade

Washer Options

- High-pressure washing system

- Rising header nozzles

- Canister/Bag filtration unit

- Tube axial steam extraction fan

- Single-point drain and supply connections

- Automatic water make-up system

- Washer interior lights

- No-spill cap plug collection tray

- Washer load and unload containment pans

- Automatic detergent dosing pump

- Wash solution heater options

Sanitizing Options+

- Final rinse pump

- Integrated ozone contact system

- Ozonator System

- Oxonia system

Equipment Add-ons

- In-line pre-washer

- Clean in Place (CIP) System

- Ozone Generator

- Contact Tank

- Modular Fill Room

- Cap Hopper and Elevator

- DeCapper Unit

- Video Jet Printer-optional

- Leak Detector

- Contaminant Detector

- RO, pre-treatment, and post-treatment filtration

- RO systems

- Softeners

- Carbon filtration

- Clarification filtration

- UV systems

- Storage solutions

- Visual light inspection station

- Crossover bridge-walkway

- Shrink-band applicator with heat tunnel

- Robotic solutions

- Rack washer

READY TO GET STARTED?

Contact US TODAY for a Quote OR AN APPOINTMENT.

Velocity Equipment Solutions Global Headquarters

2618 West State Street

New Castle, PA 16101, USA

TOLL FREE: 800-521-1368

UK Sales Office and Distribution Center

Units 4 E+F, Manor Business Park, Grants Hill Way

Woodford Halse, Nhants, NN113UB

United Kingdom