Blow Mold Machine Rebuilds

Maximize Your Investment

Whether a machine simply wears out or your production needs change, it’s a fact of life that nothing lasts forever. However…Velocity Equipment Solutions can ensure you get the maximum benefit from your blow mold machinery. If you own an aging machine that cannot meet your current capacity needs, you’re losing money. You don’t have to invest in a brand new machine to meet product demand. Instead, for a fraction of the cost of a new blow mold machine, the professionals at Velocity Equipment Solutions can rebuild and/or upgrade your current machine to match the performance of a new machine.

GET A QUOTERebuilds & Upgrades by Velocity Equipment Solutions

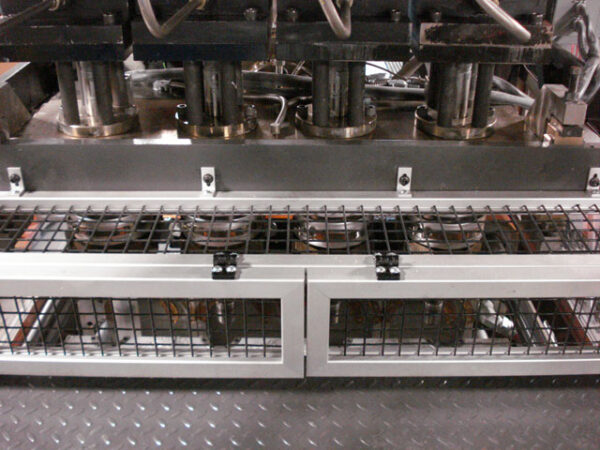

BEFORE

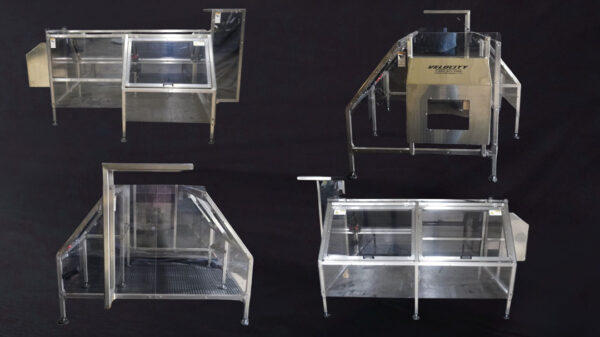

AFTER

Experience Gets the Job Done

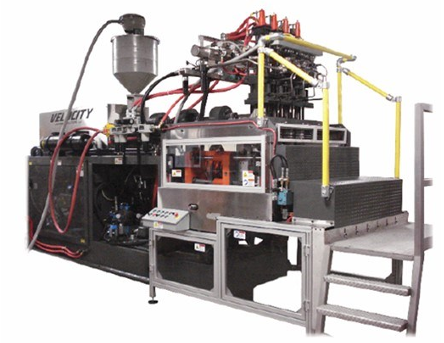

With more than 30 years of practical hands-on experience in maintaining and upgrading Uniloy, Liberty, and Portola Blow Mold equipment, Velocity Equipment Solutions has the professional acumen necessary to perform total frame-off rebuilds and upgrades. Our team has the talent and resources to make your equipment run better, faster, and more efficiently, providing all the benefits of new equipment without the high price tag.

Consider that many machines built by Velocity 30+ years ago are still in use today.

We know how to build them…and we’re just as talented when it comes to rebuilding and upgrading them.

Upgrade Options

Increase efficiency, reduce maintenance, extend performance life, and avoid the need to buy new machinery with custom upgrades by Velocity Equipment Solutions. Our upgrade options include:

UPGRADE |

MAJOR BENEFITS |

| Thunderbolt Drive | Lorem ipsum dorem lorem ipsum. Lorem ipsum dorem lorem ipsum. Lorem ipsum dorem lorem ipsum |

| Air Barrel Cooling | Eliminates the need for heat transfer fluid & chiller, reduces maintenance expense |

| Cooling Bed | Safer & more reliable. Improved controls. |

| High Flow Hydraulic Power Unit | Easier to set-up, operate & troubleshoot. Longer Pump Life. Improved cycle time. |

| High Flow Air System | Allows faster cycle time. More reliable. |

| Front Die Adjust | Faster, easier & safer adjustments that produce better bottles. |

| Servo Drive Swing Arm | More consistent, accurate control. More reliable. |

| Servo Trimmer Retrofit | Greater reliability and more accurate machine positioning. |

| PLC(s) | Eliminates counter & relays. Replaces unsupported PLC’s and or relays. Eliminates external heat controls. Provides more reliable results. |

| Rebuilt Trimmer | Greater reliability. Meets current ANSI and CE regulations for machine guarding. |

| Sliding Safety Door | Safer, more secure. Larger opening for adjustments. |

| Aluminum Swing Arm Assemblies | Consistent gripping of bottles for less downtime. Longer life of the swing arm rotary. |

| Crossover Catwalk | Safer reach to hand adjustments. Keeps dirt off bottles. |

| “Z” Steps & Guards | Safer, more secure. Large opening for adjustments. |

Uncovering the Possibilities

The first step is to determine exactly what steps are necessary to restore your blow mold machine to peak efficiency. To accurately determine your needs, one of our skilled equipment experts will discuss the condition of your equipment with your operations and/or maintenance managers. Our assessment of your current blow molding system will include:

- A comprehensive and precise assessment of your blow molding system’s current condition

- A detailed list of the corrections and/or maintenance updates necessary to restore/maintain your machine’s best possible performance

- Recommendations on actions that will extend the service life of your blow molding system and/or improve its quality and productivity through specific upgrades and/or rebuilds.

Rebuilding the way it should have been built the first time

It starts with tearing the machine down to the bare frame. We re-machine all critical surfaces. We then sandblast and repaint the frame and any reusable components, such as platens and trimmer bases. Upon completion of the refinishing process, we build your machine from the ground up, applying the latest innovations and technologies: many of which didn’t exist when the machine was originally manufactured. This results in a machine that is built stronger, more dependable, and more efficient than it was at the factory and meets all the current safety guidelines.

READY TO GET STARTED?

Contact US TODAY for a Quote OR AN APPOINTMENT.

Velocity Equipment Solutions Global Headquarters

2618 West State Street

New Castle, PA 16101, USA

TOLL FREE: 800-521-1368

UK Sales Office and Distribution Center

Units 4 E+F, Manor Business Park, Grants Hill Way

Woodford Halse, Nhants, NN113UB

United Kingdom